Reduce waste while increasing quality assurance.Being proactive with just-in-time management saves you the headache of overseeing more than you need to. Warehouse fees can get expensive and the more stock you have, the higher the overhead will likely be. Is it making you any money if you’re not using it? Probably not. If there ever is a hiccup with a delivery, your ERP solution can tell you exactly which order the delayed supplies were meant for - keeping you in the loop for a quick solution. By being able to connect anytime, anywhere, and with ease, there’s nothing standing in the way of communication between you and your customers or vendors. Communication delays can cripple operations: if you don’t know there’s a problem, it’s pretty hard to respond to it. Taking out the guesswork saves time and effort for everyone involved so that the entire team can focus on what really matters - getting things done. Lead time can be significantly reduced when you know that you can expect supplies to arrive at the exact time you need them for production. In nearly all industries (especially within manufacturing and distribution), time equals money.

Create time efficiencies and increase productivity.

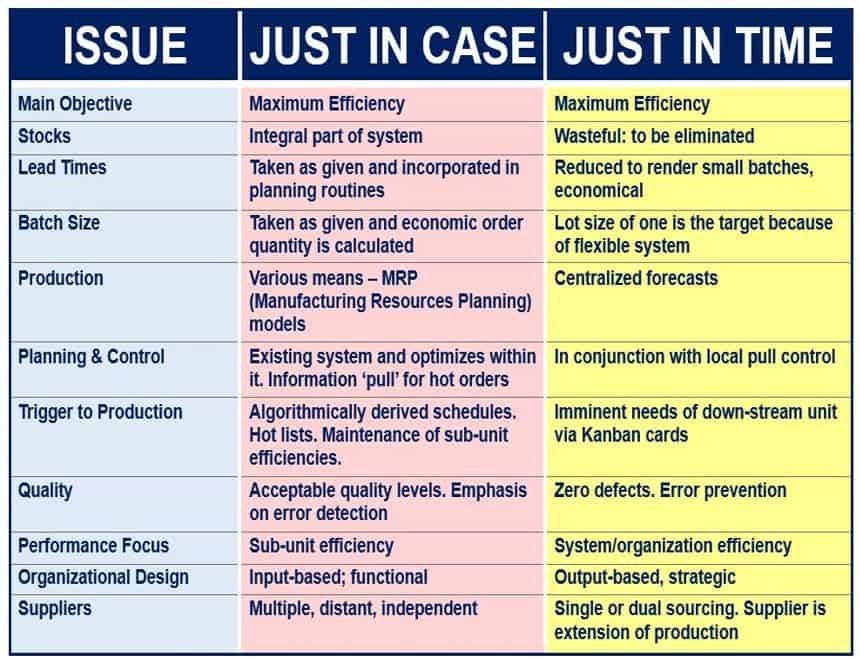

With just-in-time management, you’re only investing in what you need when you need it, giving you a lot more breathing room to use that cash for just about anything else. And no one wants to have the majority of it sunk into excess inventory. There is a plethora of advantages that come with a just-in-time strategy, but here are the top five reasons your business should use it: Just-in-time management through a reliable, cloud-based ERP helps prevent costly overages or shortages and unexpected delays by enabling instantaneous communication. How JIT Inventory Management Can Impact Your Business Implementing automation practices associated with just-in-time management keeps you from unnecessarily overcomplicating the process while minimizing the amount of inventory on hand and making room for efficiencies. Manually placing orders for supplies to keep up with growing demand can become tedious and leave room for inaccuracy. If your business is growing (we hope it is), then you’ll need to be proactive about the pains that come with scaling your operations. Employing this operational principle can be effective for many growing distributors and manufacturers looking for a more lean approach. Just-in-time inventory management typically involves implementing some levels of automation, barcoding, and cloud communication. In contrast to a traditional inventory model, or a “just-in-case” method, goods are received only as they are needed - reducing waste and inventory costs.

Just-in-time inventory management is a strategy that coordinates the delivery of supplies directly with the production and fulfillment schedule. What is Just-in-Time (JIT) Inventory Management?

What’s holding your operational processes back?Īre you plagued with communication delays from your suppliers and vendors - discovering a change in availability only after it’s too late? Are you spending too much money on storage fees for inventory - most of which you don’t even need to have on hand? Well, there’s a tried-and-true inventory management principle that’ll get you exactly where you need to be, just in time.

0 kommentar(er)

0 kommentar(er)